ALUMINUM ANODISING

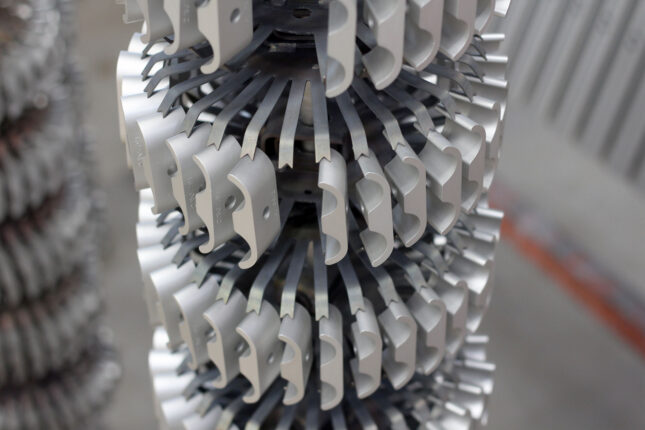

At Åre Produktion, we offer anodizing of aluminum as part of our surface treatment service. With a focus on both aesthetics and function, we create durable and corrosion-resistant surfaces suitable for technical components, design products and industrial details.

Anodizing of aluminum for durable and stylish surfaces

Anodizing – also known as aluminum anodizing – is an electrolytic process that transforms the surface layer of aluminum into a protective oxide layer. The result is an anodized surface that not only resists wear, but also provides an aesthetically pleasing finish. We can customize both color and shine to your liking.

This is how anodizing aluminum works

Anodizing is an electrolytic surface treatment method that strengthens the natural oxide layer on the aluminum surface. By immersing the component in an acid bath and passing a direct current through the material, a dense and durable layer is formed that protects against corrosion and mechanical wear.

This process is particularly useful when you want to create anodized aluminum that combines high strength with a smooth and professional finish. The anodizing itself seals the pores in the surface layer and makes the aluminum up to 3,000 times more resistant – almost as hard as diamond. It is an effective and sustainable solution for anyone who works with aluminum surface treatment in, for example, electronics, construction, vehicles or design products.

Anodizing aluminum is an obvious step when striving for both function and aesthetics. The process is also environmentally friendly and gives the aluminum a longer life while maintaining its quality

The effect of anodizing on durability and shine

How anodized aluminum looks – and how durable it is – depends largely on the treatment time and current strength. A more intensive process provides a thicker protective layer and thus better corrosion protection and wear resistance. At the same time, it can give a slightly duller finish, since a stronger surface treatment means that the surface is etched harder.

With the right settings, it is possible to achieve a balance between durability and aesthetics. A surface treatment of aluminum can therefore be adapted based on whether you prioritize a high-gloss, decorative surface – or maximum function for tough environments.

We help you choose the right method for your specific needs, regardless of whether you need anodizing of aluminum components, surface treatment of aluminum for industrial purposes or anodizing for visible design surfaces.

Efficient surface treatment with a focus on delivery and flexibility

We work with both small and large series and can offer fast delivery and high flexibility. Our facility is optimized to deliver both standard and customized surface treatments, where anodizing in aluminum is often an obvious choice.

Do you want advice on which surface treatment suits your product best? Contact us – we will help you develop the right solution, regardless of whether you are looking for function, design or both.